To our customers: please note that there are fake NCX seatposts out there in the market.

Read our updated (as of December 2024) counterfeit product announcement for more information.

- Products

-

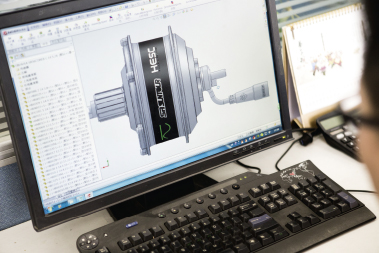

Tech & Features

-

Key Technologies

-

RC+ Cartridge

Ride bold!

-

EQ EQUALIZER™ SYSTEM

For precise & effortless tuning

-

PCS SYSTEM

More traction, control and consistency

-

SOBA TECHNOLOGY

Semiopen Oil Bath

-

5TA

Changing the Status Quo

-

DAMPING ADJUSTMENT

Explanation of our function names

- ADJUSTABLE AIR CHAMBER VOLUME

-

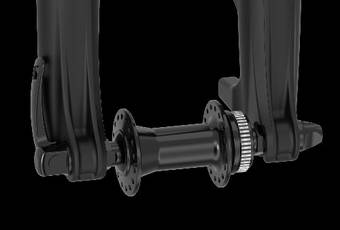

Q-LOC SYSTEM

Thru axle quick release

-

LIGHTWEIGHT CROWN TECHNOLOGY

Hollow & Carbon crown

-

QSP QUICK SERVICE PRODUCT

Ride more, wrench less.

-

- Support

- Company

-

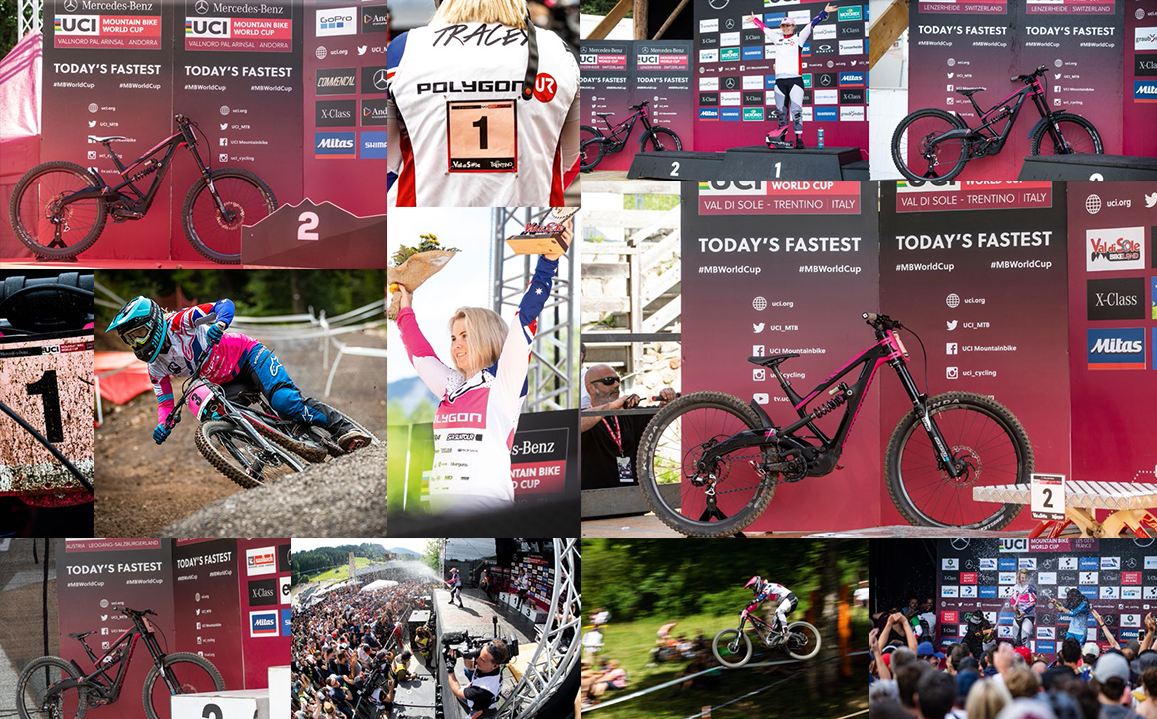

Stories

-

News

- Contact

-

Shop

You are now entering the online shop of SR SUNTOUR North America.

Enter the shopI am aware that extra costs such as shipping, import duties can occur and that delivery times can be longer than mentioned in the terms and conditions of the SR SUNTOUR USA Webshop.