Ai nostri clienti: si prega di notare che sul mercato sono presenti falsi reggisella NCX.

Leggere il nostro annuncio di prodotto contraffatto aggiornato (a dicembre 2024) counterfeit product announcement per maggiori informazioni.

-

Prodotti

-

Tech & Features

-

Key Technologies

-

Cartuccia RC+

Ride bold!

-

EQ EQUALIZER™ SYSTEM

For precise & effortless tuning

-

SISTEMA PCS

Maggiore trazione, controllo e costanza

- TECNOLOGIA SOBA

-

5TA

Cambiare lo status quo

- REGOLAZIONE SMORZAMENTO

- VOLUME REGOLABILE DELLA CAMERA D'ARIA

-

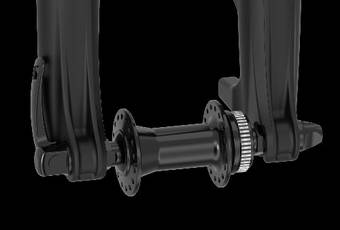

Q-LOC SYSTEM

Thru axle quick release

-

LIGHTWEIGHT CROWN TECHNOLOGY

Hollow & Carbon crown

-

PRODOTTO QSP QUICK SERVICE

Guida di più, usa meno chiavi.

-

- Support

- Azienda

-

Storie

-

Novità

- Contatto

-

Negozio

Stai entrando nel negozio online di SR SUNTOUR Nord America.

Entra nel negozioSono consapevole che possono verificarsi costi aggiuntivi quali spedizione e dazi di importazione e che i tempi di consegna possono essere più lunghi di quelli indicati nei termini e condizioni del Webshop SR SUNTOUR USA.